Single-cylinder hydraulic cone crusher is the introduction of foreign advanced technology is widely used in metallurgy, construction, highway, chemical industry, building materials industry, suitable for crushing high hardness and high abrasive ores and rocks, especially in the metal mines and construction sand and gravel crushing the most widely used;

The main shaft of single-cylinder hydraulic cone crusher adopts upper and lower supports, when working, the motor drives the pinion gear of the crusher, the pinion gear drives the large gear, the large gear assembly (large gear, large gear frame, eccentric steel sleeve) drives the eccentric sleeve assembly (eccentric cylinder sleeve, eccentric copper sleeve) and the spindle assembly (spindle, inner cone, inner cone liner) to the centre of the theoretical vertical line, rotating in the copper sleeve, the spindle assembly can rotate with the centerline of the spindle in the eccentric copper sleeve. The main shaft assembly in the eccentric copper bushing can rotate by the centre line of the main shaft. When the material enters into the crushing chamber, the main shaft assembly (main shaft, inner cone) rotates slowly in the eccentric copper bushing under the resistance of the material. The running track of the inner cone appears to be swinging back and forth in the crushing chamber while rotating slowly. The material is crushed by the swinging inner cone. The support sleeve and the frame are connected by the hydraulic cylinder pressure, when the crusher falls into the metal block and other unbreakable objects, the single-cylinder cone is lifted up by the hydraulic piston at the bottom, which plays the role of discharge port adjustment and over-ferrous iron protection, and repeatedly lifting and lowering to exclude the clogging of the ore.

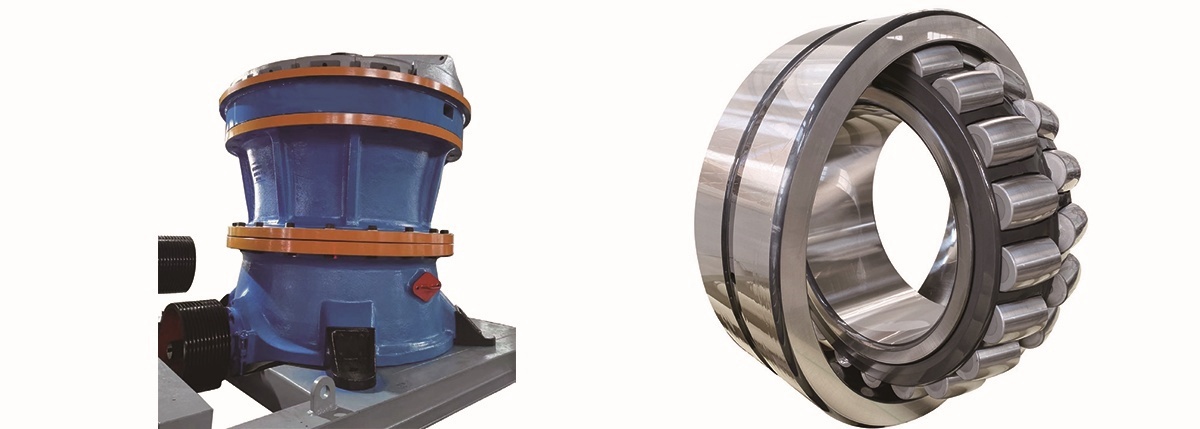

STE has developed special spherical roller bearings for single-cylinder hydraulic cone crushers. For more information about single-cylinder hydraulic cone crusher bearings, please contact STE service personnel.