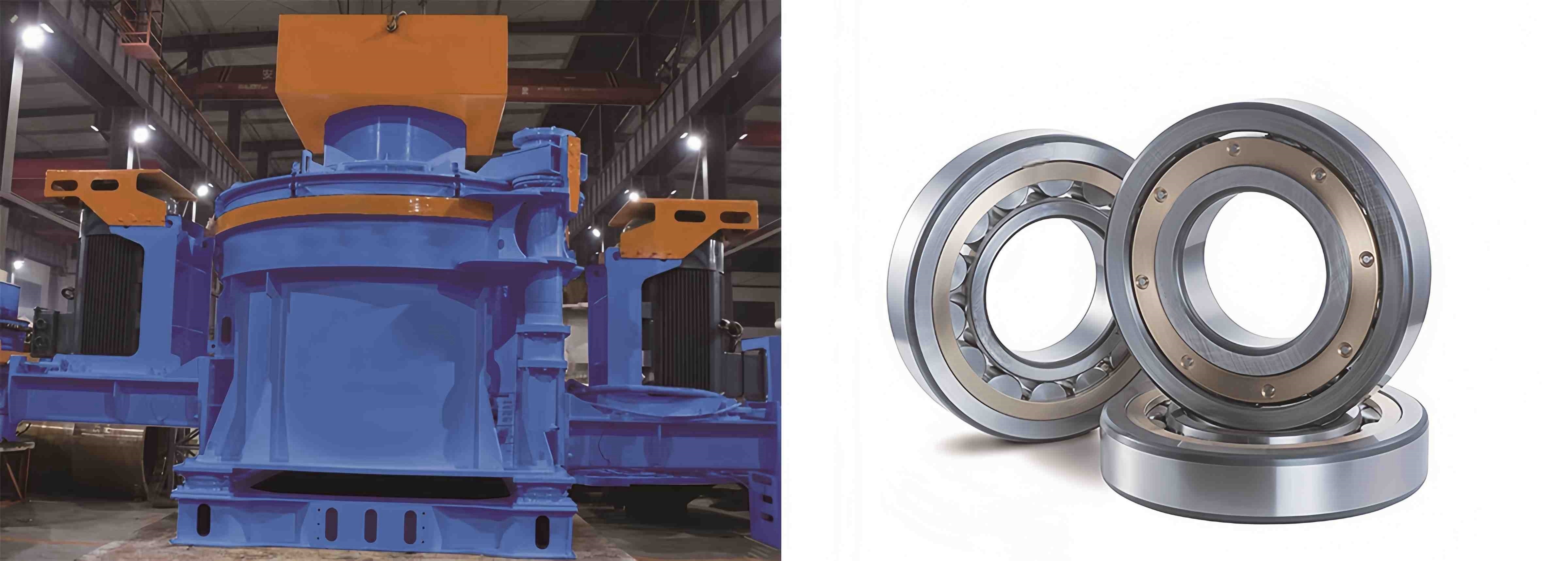

Vertical Shaft Impact Crusher is used when the material is fed into the crusher through a hopper with a material village, and there is a hydraulic gate at the bottom of the hopper to control the amount of material fed into the rotor, and the material is fed into the feeding pipe under the action of its own gravity, and then given to the rotor along the feeding pipe, and the motor-driven pulley drives the rotor to rotate at a high speed. After the material enters the rotor, it is accelerated to 45-72m/s under the action of centrifugal force of high speed rotation. Then the material is thrown along the deflector plate of the rotor at high speed. The high-speed materials launched from the rotor collide fiercely with the materials piled up in the crushing chamber or the guard plate, and the impact, splitting and grinding effects are produced through the high-speed collision of the stones, thus achieving the purpose of crushing.

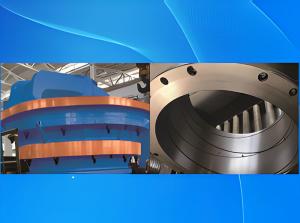

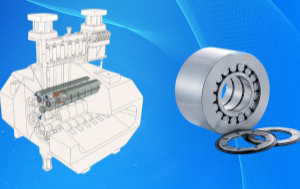

The transmission bearing of the vertical shaft impact crusher consists of a deep groove ball bearing and two to three cylindrical roller bearings. The deep groove ball bearing has to ensure the axial positioning of the vertical shaft while running at high speed. Sengemeier engineers through years of research and development design, increase the deep groove ball bearing axial bearing capacity, so that its life increased by 30 per cent. At the same time, the internal structure of the cylindrical roller bearings was optimised to increase the limiting speed and reduce wear.

STE has developed special cylindrical roller bearings and deep groove ball bearings for Vertical Shaft Impact Crushers, please contact STE service personnel for more information about special bearings for Vertical Shaft Impact Crushers.